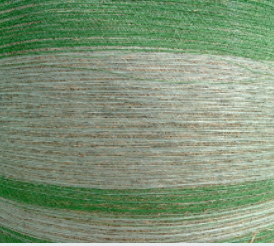

Silage wrap is a plastic film used to preserve and protect crops. It is made from a high-quality material that can withstand harsh weather conditions. The material is also environmentally friendly and easy to use.

It helps farmers preserve their forage quality by limiting oxygen and creating a tight seal. It also prevents moisture penetration into the soil. For professional silage wrap forage management services, click here.

Quality

A high-quality silage wrap can significantly reduce the amount of moisture and oxygen that enters a bale, preserving the nutritional value of the crops. It also protects against insects and other pests that might damage the crop. However, not all silage wrappings are created equal. To make sure that you choose the right one for your needs, there are several factors that you should consider, such as clarity, strength, chemical resistance, and texture. The most crucial factor is permeability, which determines how much oxygen and moisture can pass through the film. If the silage is exposed to too much water and oxygen, it will spoil and lose value.

A high-quality silage wrap can significantly reduce the amount of moisture and oxygen that enters a bale, preserving the nutritional value of the crops. It also protects against insects and other pests that might damage the crop. However, not all silage wrappings are created equal. To make sure that you choose the right one for your needs, there are several factors that you should consider, such as clarity, strength, chemical resistance, and texture. The most crucial factor is permeability, which determines how much oxygen and moisture can pass through the film. If the silage is exposed to too much water and oxygen, it will spoil and lose value.

A good silage wrap is made of a type of plastic that is resistant to both biotic and abiotic factors. Known as low-density polyethylene, or LDPE, this plastic is made of recycled material and can help reduce the amount of waste produced by farmers. Silage wrap can also withstand harsh weather conditions, including strong winds and rains.

The thickness of the silage wrap is also essential, as it will determine how long it can withstand exposure to sunlight. This is why selecting a wrap with a high tensile strength is necessary. This measures how much stress a material can withstand before it begins to stretch or break. Fortunately, most silage wraps have a tensile strength of over 150 MPa.

Whether you’re making hay or straw bales, you must protect them from the elements to preserve their quality and nutrition. The best way to do this is by using a high-quality silage wrap. The wrap will keep the bales clean and safe from insects, crows, and rodents. It will also help you avoid bringing the bales indoors for storage.

Many co-ops produce own-brand bale wrap (film) of various specifications. While standard 750mm x 1,500m rolls are the most popular, there are alternatives. Silotite and Volac make longer-length films, allowing you to wrap more giant bales with fewer layers. Alternatively, you can use Silawrap, manufactured in Gorey, Co. Wexford. This film is more durable than other leading brands and offers a quality edge trim for hassle-free wrapping.

Durability

Choosing a durable silage wrap is one of the most important decisions farmers must make. This is because the quality of a film will determine how well it protects feed from oxygen and moisture. Several factors affect the durability of a silage film, including its tensile strength and thickness. These factors determine how much force the plastic can withstand before stretching and breaking. In addition, the type of plastic used plays a role in its durability. For example, some plastics are more flexible than others.

Another factor is the permeability of a silage film. The silage will spoil if the film allows oxygen and moisture to pass through. To ensure your grass’s integrity, choose a low-permeability film. Generally, silage films with a permeability of less than 10 microns are good choices.

Stacking your bales on their barrel side is recommended to reduce damage to the silage wrap and prevent air leakage. This will also help keep the cling levels high and allow your bales to ferment correctly. In addition, you should store your bales close to where they will be consumed to minimize handling and risk of damage.

Many people use regular plastic wrap for silage bales because it is cheaper than unique silage wrap. However, if you are concerned about the environmental impact of plastic waste, you should consider using a biodegradable product instead. Fortunately, many companies manufacture a biodegradable film for silage bales.

The cost of a silage wrap varies from company to company, but the average price is around EUR 83 per roll. However, there are price differences based on the brand and colour of the wrap. Some suppliers also offer discounts if you buy a certain amount of silage wrap.

A silage wrap should be made of a non-permeable material to prevent contamination from rodents and other insects. In addition, the wrapping should be made of a material that can be easily fabricated on-farm and sprayed on bales. Moreover, the wrapping should be durable enough to withstand severe weather conditions.

Environment-friendly

Consider using plastic silage wrap if you’re looking for an environment-friendly way to preserve your grass. This polyethylene material protects hay and straw bales from moisture, air, and other elements. This allows you to store hay and straw in large quantities without losing the nutritional value of the crops. It also helps you save money by reducing dependence on expensive industrial feed. For professional silage wrap forage management services, click here.

SML brands for silage film are the leading suppliers of high-quality, reusable and durable packaging. The SML process allows producers to create a range of reusable, durable products with minimal production costs. The SML SmartCast line produces 4 x 750mm rolls, offering double the output of a standard blown film line. In addition, the line also produces stretch wrap film and silage film. Despite the production methods, both types of SML products deliver high-quality products.

SML brands for silage film are the leading suppliers of high-quality, reusable and durable packaging. The SML process allows producers to create a range of reusable, durable products with minimal production costs. The SML SmartCast line produces 4 x 750mm rolls, offering double the output of a standard blown film line. In addition, the line also produces stretch wrap film and silage film. Despite the production methods, both types of SML products deliver high-quality products.