SML has several different brands if you are looking for a good silage film. Some of the most popular are POLIFILM, MINI CAST, SUN REFLECT, and Mini-Cast. Here, we will discuss the benefits of each brand and why it is essential to use them on your farm. These brands have positive attributes, but we want to help you choose the best silage film for your situation.

SML brands for silage film

SML brands for silage film are the leading suppliers of high-quality, reusable and durable packaging. The SML process allows producers to create a range of reusable, durable products with minimal production costs. The SML SmartCast line produces 4 x 750mm rolls, offering double the output of a standard blown film line. In addition, the line also produces stretch wrap film and silage film. Despite the production methods, both types of SML products deliver high-quality products.

SML brands for silage film are the leading suppliers of high-quality, reusable and durable packaging. The SML process allows producers to create a range of reusable, durable products with minimal production costs. The SML SmartCast line produces 4 x 750mm rolls, offering double the output of a standard blown film line. In addition, the line also produces stretch wrap film and silage film. Despite the production methods, both types of SML products deliver high-quality products.

SilageWrap silage film is certified by the Blue Angel, one of the most demanding environmental certifications. This certification demonstrates its commitment to responsible agriculture and ensures that its products contain at least 80% recycled material. SML’s formulation also contains a UV masterbatch, which helps protect goods from ultraviolet light. In addition, PIB-free products have a cling level of eight to nine N/m, higher than the industry standard.

POLIFILM

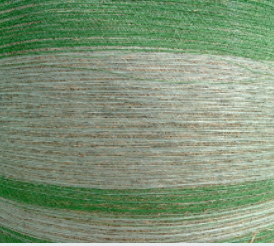

The agricultural sector is one of the main focuses of POLIFILM, a German manufacturer of agricultural stretch film. These products ensure the best possible harvest utilisation and higher yield. Agricultural films manufactured by POLIFILM are designed to prevent hay from spoiling during transport. They are ideal for baled and bunker silos and are highly effective at reducing the risk of rotting. Their films are designed to handle quickly and provide optimum mechanical and chemical protection for silage. The film is in green, black and white and is available in sizes 500 x 1800 m.

POLIFILM is a leading manufacturer of PE films in Germany. Its films are recyclable and made of high-quality raw materials. Its biodegradable films help reduce waste and support organic recycling. The films are 100% biodegradable and can be reused without problems. POLIFILM also works to support the environment and is a founding member of “ERDE.”

SUN REFLECT

SUN REFLECT silage film has outstanding mechanical properties. Available in black/white, green/white, and white/black, these films have exceptional elasticity and are designed to last up to 15 months. Furthermore, these products are made without using reclaimed rubber. As a result, they do not damage the bales and are highly resistant to punctures. In addition, the film can be rolled up and transported directly to collection points.

This film is pre-stretch up to 75% and has no strength or UV durability reduction. It is the leading hay wrap plastic on the market and is made in the United States by AEP, one of the world’s largest manufacturers of polyethylene products. The benefits of using SUN REFLECT silage film are numerous. This film is designed to prevent a buildup of fungi and bacteria and helps preserve the nutritional content of the bale.

MiniCast

PIB-free cast SilageWrap silage film from SML is designed to achieve stickiness levels of about 8,500 cm3/m2*24h. It is formulated with a UV master batch that protects goods from sunlight. Compared to PIB-based film, its cling value was about eight to nine N/m, while its stretchability was nearly 300 per cent at 750 mm rolls.

SmartCast

The stretchability and reliability of SmartCast silage film are unmatched. Its inner layers are guaranteed to provide the correct dart impact and stretchability, which are essential in protecting silage. The film is typically required to be stretchable from 50 to 100 per cent. Here are three benefits of SmartCast silage film. All three qualities contribute to its superior quality. And, what’s more, it’s completely recyclable.

Trioplast’s latest development in silage film

The company’s latest silage stretch film utilises recycled polyethylene (PCR) as raw material, allowing it to provide superior oxygen barrier properties and reduce the carbon footprint of the entire production process. The company has patented this technology and distributes it throughout the world. Trioplast is the leading producer of polyethylene film, and their latest development uses PCR to provide an environmentally friendly, sustainable option for bale wraps.